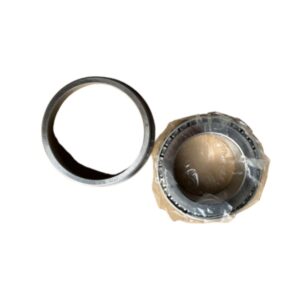

As a premier supplier of Sinotruk spare parts, we offer the high-performance ZF Transmission Synchronizer Cone Hub (Part Number: 1297 304 523). This component is the central element of the synchronizer assembly in ZF 16-speed gearboxes (such as the 16S2530 and 16S221), which are the standard transmission systems for Sinotruk HOWO 371, HOWO A7, and SITRAK heavy-duty trucks.

When sourcing Sinotruk spare parts, precision is non-negotiable. Our Synchronizer Cone Hub is manufactured to OEM standards, ensuring seamless gear engagement, reduced shift effort, and extended transmission lifespan under the grueling conditions of mining and long-haul logistics.

Technical Specifications

-

Part Name: Synchronizer Cone Hub / Synchronizer Body

-

OEM Part Number: 1297 304 523 (Also interchangeable with ZF cross-reference numbers)

-

Application: ZF Ecosplit Gearbox (16S151 / 16S181 / 16S221 / 16S251)

-

Vehicle Compatibility: Sinotruk HOWO 6×4 Dump Truck, 8×4 Cargo Truck, Tractor Heads

-

Material: 20CrMnTi (High-grade Carburized Gear Steel)

-

Spline Design: Precision-cut internal splines for secure shaft locking.

-

Hardness: Surface HRC 58-62; Core HRC 30-45 (Ensuring wear resistance on teeth and toughness in the core)

-

Processing: Forging -> Normalizing -> Rough Machining -> Carburizing -> Fine Grinding

-

Weight: Approx. 1.45 kg

Why Choose Our Sinotruk Gearbox Parts?

-

Exact Fitment: Designed specifically for the ZF transmission architecture used in Sinotruk chassis, preventing “gear pop-out” issues.

-

Heat Resistance: Engineered to withstand the high thermal stress of frequent shifting in heavy-load scenarios.

-

Comprehensive Inventory: We are your one-stop hub for all Sinotruk spare parts, allowing you to combine this hub with sliding sleeves, synchronizer rings, and bearings in a single shipment.

Installation & Maintenance Tips

-

Synchronizer Assembly Check: When replacing the Cone Hub (1297 304 523), it is critical to inspect the mating Sliding Sleeve and Synchronizer Ring. Installing a new hub with worn rings will lead to rapid failure of the new part.

-

Clean Assembly: Ensure the main shaft splines are completely clean of metal shavings before sliding the new hub into place. Even small debris can cause the hub to seize.

-

Orientation: Although the hub may look symmetrical, check for any directional markings or chamfers indicated in the ZF repair manual to ensure the correct side faces the gear.

-

Lubrication: Pre-coat the internal splines and external teeth with transmission fluid (SAE 85W/90) to facilitate smooth initial operation.

Reviews

There are no reviews yet.