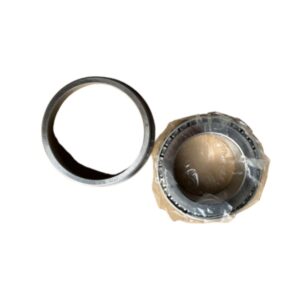

Genuine SINOTRUK HOWO N WP12/WP13 Exhaust Manifold Gasket (1009931855) is the critical sealing component that ensures every ounce of exhaust energy is channeled efficiently to the turbocharger. As a vital piece of sinotruk spare parts, its failure can lead to a significant drop in turbo boost, increased fuel consumption, and the tell-tale “ticking” sound of an exhaust leak.

Technical Specifications

The 1009931855 gasket is a high-temperature sealing component for the WP12/WP13 engine series.

|

Specification

|

Value

|

|

Part Number

|

1009931855

|

|

Alternative Names

|

Exhaust Pipe Gasket, MLS Manifold Gasket

|

|

Product Name

|

Exhaust Manifold Gasket

|

|

Engine Model

|

Weichai WP12, WP13 (400hp+ configurations)

|

|

Compatible Vehicles

|

SINOTRUK HOWO N, HOWO T7H, SITRAK

|

|

Brand

|

SINOTRUK (Original OEM Specification)

|

|

Material

|

Multi-Layer Steel (MLS) / High-Temp Alloy

|

|

Construction

|

Typically 4-Layer Reinforced

|

|

Temperature Resistance

|

Up to 800°C

|

|

Function

|

Seals exhaust gas between cylinder head and manifold

|

|

Condition

|

Brand New

|

Installation Notes

Exhaust manifold gasket replacement is a common maintenance task, but it requires precision to ensure a lasting seal.

1.Safety and Preparation: Ensure the engine is completely cold before starting work, as exhaust components retain heat for a long time. Disconnect the battery.

2.Manifold Removal: Carefully remove the heat shields and the turbocharger (if necessary). Unbolt the exhaust manifold. Due to heat cycling, manifold bolts can be brittle; use penetrating oil and a six-point socket to avoid rounding or snapping them.

3.Surface Cleaning (Critical): Use a gasket scraper and a fine wire brush to meticulously clean the mating surfaces on both the cylinder head and the exhaust manifold. The surfaces must be perfectly flat and free of all carbon deposits and old gasket material. Any residue will create a leak path.

4.Gasket Orientation: Place the new 1009931855 gaskets onto the cylinder head studs. Ensure the gasket is oriented correctly (usually the raised sealing bead faces the manifold).

5.Torque Sequence: Reinstall the manifold and bolts. Apply a small amount of high-temperature anti-seize compound to the bolt threads. Tighten the bolts in a specific sequence (starting from the center and working outwards) to the manufacturer’s specified torque. This ensures even pressure across all ports.

6.Post-Installation Check: Start the engine and listen for the characteristic “ticking” sound of an exhaust leak. Re-torque the manifold bolts after the engine has run for a full heat cycle and then cooled down completely.

Reviews

There are no reviews yet.