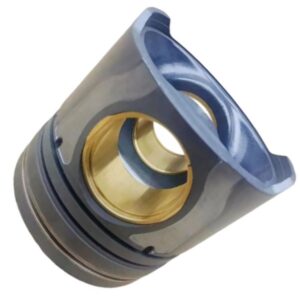

The engine piston is the component that converts the explosive power of combustion into usable mechanical energy. For the high-performance WD615 engine found in the SINOTRUK HOWO 371, this conversion happens under extreme conditions of heat, pressure, and speed. The Genuine SINOTRUK HOWO 371 Engine Piston (VG1560037011) is engineered to withstand this relentless environment. As a fundamental component among sinotruk spare parts, its integrity is non-negotiable for maintaining the engine’s rated horsepower and fuel efficiency.

Technical Specifications

The VG1560037011 piston is a precision-engineered component for the high-output WD615 engine series.

|

Specification

|

Value

|

|

Part Number

|

VG1560037011

|

|

Alternative Names

|

Piston Assembly, WD615 Piston

|

|

Product Name

|

Engine Piston

|

|

Engine Model

|

WD615.47 (371hp), WD615.69 (336hp)

|

|

Compatible Vehicles

|

SINOTRUK HOWO 371, HOWO A7, and other WD615-equipped trucks

|

|

Brand

|

SINOTRUK (Original OEM Specification)

|

|

Material

|

High-Strength Aluminum Alloy

|

|

Diameter (Approx.)

|

126mm

|

|

Design Feature

|

Dished/Concave Crown (Combustion Bowl)

|

|

Function

|

Converts combustion energy into mechanical force

|

|

Weight (Approx.)

|

2.1 KG

|

|

Condition

|

Brand New

|

Installation Notes

Piston replacement is a major engine overhaul procedure that requires specialized knowledge, tools, and a surgically clean environment. This work must be performed by a certified diesel engine technician.

1.Engine Disassembly: The engine must be partially or fully disassembled to access the cylinder block. The cylinder head and oil pan must be removed.

2.Cleanliness is Paramount: The work area and all components must be absolutely clean. Even a single grain of dirt can cause immediate scuffing of the cylinder liner and premature failure of the new piston.

3.Piston Orientation: Before installation, the piston rings must be correctly installed and their gaps staggered. Crucially, the “Front” mark (usually an arrow or notch) on the piston crown MUST point towards the front of the engine (timing gear side). Installing the piston backward will misalign the combustion bowl with the fuel injector, leading to poor combustion and potential damage.

4.Lubrication: Apply a generous amount of clean, new engine oil to the piston skirt, piston rings, and the cylinder liner before insertion. Use a piston ring compressor to guide the piston into the cylinder bore.

5.Torque Specifications: The connecting rod bolts must be torqued to the manufacturer’s exact specifications, often using a precise torque-plus-angle method. Incorrect torque will lead to bearing failure or rod cap separation.

6.Break-in Procedure: After the engine is reassembled, a strict break-in procedure must be followed, avoiding full load for the first few hours of operation to allow the new piston rings to seat properly against the cylinder liner.

Reviews

There are no reviews yet.