Enhance Your Engine Performance with Genuine MAN MC07 Technology

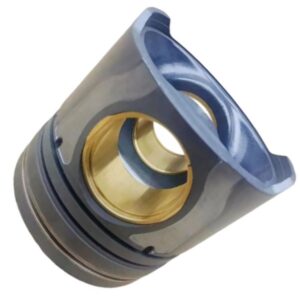

The 080V02503-6810 Piston Ring Assembly is a critical component specifically engineered for the Sinotruk T5G series equipped with MAN MC07 engines. As a vital part of your howo truck parts inventory, these rings ensure optimal cylinder sealing, efficient heat transfer, and regulated oil consumption.

Crafted from high-grade alloy steel and treated with advanced wear-resistant coatings, this assembly is designed to withstand the extreme thermal and mechanical stresses of heavy-duty logistics. Whether you are performing a routine overhaul or a complete engine rebuild, using genuine 080V02503-6810 parts guarantees the longevity and fuel efficiency that Sinotruk operators rely on.

Key Features:

-

Precision Fit: Specifically calibrated for the MAN MC07 engine bore.

-

Superior Material: High-strength ductile iron and chrome plating for reduced friction.

-

OEM Standard: Manufactured to the exact specifications of Sinotruk (CNHTC) to ensure 100% compatibility.

-

Durability: Enhanced resistance to high temperatures and carbon buildup.

Technical Specifications

| Feature | Specification |

| Product Name | Piston Ring Assembly |

| Part Number | 080V02503-6810 |

| Engine Model | Sinotruk MAN MC07.21 / MC07.24 / MC07.28 / MC07.31 |

| Truck Model | Sinotruk T5G, HOWO T7H (with MC07 Engine) |

| Material | High-Quality Ductile Iron / Steel Alloy |

| Coating | PVD Coating / Chrome Plating |

| Standard | OEM Genuine Spare Parts |

| Weight | Approx. 0.15 kg per set |

Professional Installation Guide

Step-by-Step Installation for 080V02503-6810 Piston Rings:

-

Cylinder Preparation: Before installation, ensure the cylinder liner is clean and inspected for wear. Apply a light coat of engine oil to the cylinder walls.

-

Ring Gap Inspection: Place each ring into the cylinder bore and use the piston to square it up. Measure the end gap using a feeler gauge to ensure it meets Sinotruk MC07 technical manual standards.

-

Correct Orientation: Identify the “TOP” mark on each ring. Ensure the marked side faces the combustion chamber (upward).

-

Sequential Fitting: Use a professional piston ring expander tool to avoid snapping the rings. Install the oil control ring first, followed by the second compression ring, and finally the top compression ring.

-

Staggering the Gaps: Position the ring gaps at 120-degree intervals around the piston. Never align the gaps with the piston pin axis or with each other to prevent “blow-by.”

-

Lubrication: Thoroughly lubricate the entire assembly with clean engine oil before inserting the piston into the block using a ring compressor

Reviews

There are no reviews yet.